The vast majority of Six Sigma proponents agree to the fact that the key to Six Sigma improvement success is the building up of an effective infrastructure. An effective infrastructure is the foundation for the success of the organization in its implementation of Six Sigma. It is also clear that the success of Six Sigma lays on the projects selected and their link to the strategy of their organization and the effectiveness of the value chain processes. There have been enough publications on the selection of projects and the filters to be used for the prioritization of projects, however there are not enough details available on the building up of the key infrastructure for the deployment of Six Sigma and its linkages to the business strategy and the organizations value chain processes.

When we discuss the building up of an implementation infrastructure what we are embarking on is a project, which follows the DMAIC (Define, Measure, Analyze, Improve and Control) methodology:

D:

Define the Strategic Direction of the organization and define the Value Chain processes

M:

Set Measures for the strategic objectives of the organization and key performance indicators for the Value Chain

A:

On a continual basis collect data on the measures set and analyze using Six Sigma tools and techniques

I:

Identify the opportunities for improvement and convert them to Six Sigma projects for improvement

C:

Set up a management control action of continuous reviews on the improvements made on the Six Sigma Projects

The objectives of the Define and Measure phase of this project are defined as below:1. Building up a set of metrics for the organization that give definition to the organization’s Vision2. Create a high level process map of the Value Chain Processes3. Metrics that are Integrated with the Strategic direction and objectives of the organization4. Metrics that align people and work with their strategic objectives5. Metrics that serve as effective means of communication for the organization both horizontally and vertically.6. Metrics that provide insight needed for making decisions, setting direction and correcting course while using the Strategic direction and the Value Chain processes for guidance.7. Metrics which will serve as a continuous source for identifying gaps in the organization and making improvements with Six Sigma ProjectsThe problem most organizations face in the phases of Define and Measure is how to build such an organizational dashboard, which will help achieve the objectives cited above.

First Step – Assessment

The first step an organization needs to embark on is conducting a self-assessment based on proven assessment models, potentially Business Process Management (BPM), which will help the organization in understanding its “as is” state more clearly and help identify the various opportunities for improvement. The organizations could use this type of approach in conjunction with interviews for identifying the gaps in Approach-Deployment-Results. Once the assessment of the organization is completed the findings need to be shared with the top management and the employees. This step is extremely crucial as this is what binds the organization together and helps create the cultural change needed aspect within the organization combined with the need for Six Sigma.

Second Step – Re-evaluate the Strategy

Once the first step is conducted the organization is now clear about its current strategies for growth and customer satisfaction. Based on the assessment conducted the organization can re-evaluate all its strategies and strategic objectives. New strategic objectives can now be identified for the levels of improvement needed to be a strong competitor in the marketplace.

Third Step – Articulate the Strategy

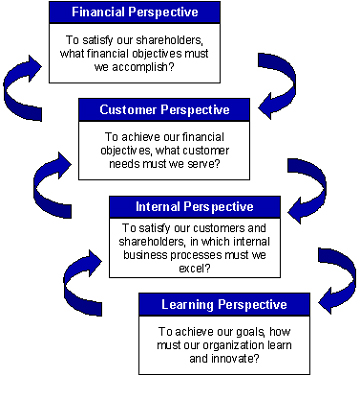

Most organizations after having articulated and identified their various objectives are unable to communicate the strategies of the organization. One of the most effective methods for communicating the strategy of the organization is building a strategy map encompassing the widely adopted Balanced score card spanning the four perspectives. Answering the questions related to the perspectives helps understand the strategy better and also build a good strategy map. The strategy map helps provide the vital cause and effect linkages in an organization and helps link the Business processes/Value Chain to the strategic direction of the organization. Before attempting to build the map it is essential for the organization to identify all its core processes and support processes as they help in completing the strategy map.

The Balanced score card perspectives help an organization to integrate and operationalize the organizations strategy.

Figure 1: The Balanced Scorecard perspectives

Once the organization has articulated the strategy the next area of concern becomes project selection. Providing Six Sigma project leaders with appropriate project definitions is an underestimated challenge in managing Six Sigma initiatives. Project charters typically contain project scopes too broad or too high level, with weak or unclear problem and goal statements. This can cause newly trained project leaders to use their precious time trying to “boil the ocean.”

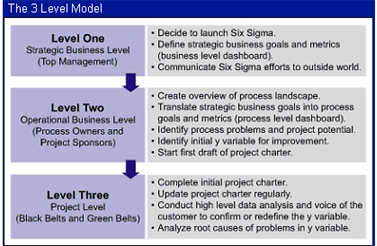

One of the key success factors for Six Sigma programs is establishing good project starting points through appropriate problem definitions. How should this be approached? A simple model (Figure 1) can explain roles and responsibilities in selecting projects. The model shows that strategic improvement initiatives need to be started at the top, and that a natural downward flow, in which everyone understands his or her role, is critical.

The Model for Identifying Successful Projects

Level 1 – Ready –

Top management decides to launch Six Sigma to confront serious business challenges (the big Y’s). These relate to the strategy and gaps in Value Chain performance.

Level 2 – Aim –

The next step is to establish people, usually in management, as process owners and project sponsors. The process owner is a role required in any company serious about process management. Project sponsors may even be recruited from senior management if their influence will effectively help the team overcome roadblocks.

The people on Level 2 look for improvement potential within the business process/value chain. To do this, they need to translate the business goals into process goals. They have to identify those processes whose outcomes (the little y’s) are currently not meeting targets and are constraints to achieving the higher level business goals. Also, they need to understand how the processes interact, so that when projects are identified, they do not cause problems in other processes up or downstream from these efforts.

Level 3 – Fire –

The resulting improvement ideas from level two are distributed to project leaders – Black Belts – as first draft project definitions. The Black Belts fine-tune their assigned project definitions, gather data and analyze the root causes of variation in their assigned y-variables.

Figure 2: The 3 Level Model

Though this sounds simple enough, in practice, many organizations initially fail to grasp or choose to overlook the importance of following the ordered top-down deployment flow. They follow a pattern of 1-3-2 (Ready – Fire – Aim) instead of 1-2-3 (Ready – Aim – Fire).

Arguably, this pattern might have some advantages, faster startup, explaining why it is so common. For example, an organization may jump from level one directly to the launching of projects at level three to get fast process improvement and financial results. The problem with this approach is that you can have several projects that will conflict with each other and in some cases negating the gains being made by working at cross purposes. However, the 1-3-2 approach often results in some serious problems that can stall a Six Sigma program and threaten its long-term success.

Conclusion: Another 1-2-3

Three key factors for Six Sigma project success – resulting in deployment success

- Define projects within the value chain processes themselves – not on the balance sheet or in the boardroom – to provide project leaders with suitable starting points.

- Improvement projects should address specific problems within defined scopes in order to avoid overwhelming resources and overextending project timelines. Also, by understanding where in the overall process you are working, you can avoid suboptimizing your improvement effort.

- Engage middle management as the program is being deployed and, in the long run, have the process owner participating in analysis work as the main link – or translator – between business imperatives and process issues.