Many large organizations lack process documentation. But how do you solve the problem of too much documentation, and not enough organization? We suggest implementing a Process Catalog.

Process awareness is growing across the company with which I am working and business units are focusing on process modeling and improvement efforts. However, this work is typically initiated by mid-level managers and neither methods nor deliverables are standardized across the company. I am working on a pilot program in a small business unit, approximately 7 departments and 50 people, to create a Process Catalog as an aid to their more detailed process modeling and improvement efforts. This and subsequent articles will chronicle the experiences and learning as this effort progresses.

What Is a Process Catalog and Why Do We Want One?

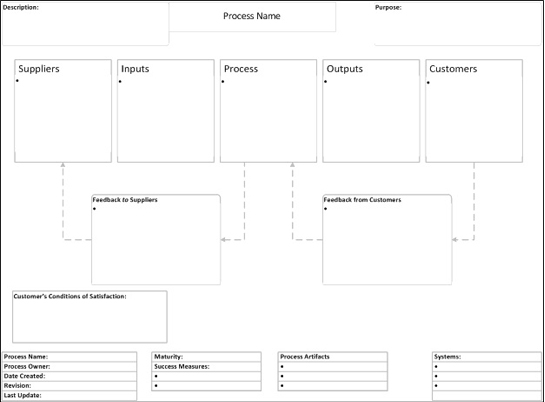

What it is: Essentially, a Process Catalog is a list that includes critical characteristics of a process. Each has a high-level diagram. These diagrams are similar to SIPOC[1] models, but they are at a lower level and include dimensions than the usual enterprise-level SIPOC.

Here is a sample of the model we are using:

What it is not: A collection of hierarchical swim lane diagrams, nor is it the As Is and To Be gap analysis done in preparation for an improvement effort. If these documents exist, they are referenced in the Process Catalog. However, at this stage there is no effort to standardize the formats or levels of, or to fill in the gaps of, more detailed process models.

What Problem Are We Solving?

In this business unit, there are no resources dedicated to process modeling or improvement. Rather, process change and improvement is driven either by technology change, or as a result of a non-standard process causing visible pain to the organization. Feedback is not formally sought or provided. There is little understanding of how individual work fits into the larger context of the organization, internal or external customers, or how they connect to the enterprise’s goals.

This large, multi-national company’s founder intentionally established competing business units, believing that best practices would naturally emerge and become standardized. For the past several years, after fundamental changes in the organization, the executives have been working to break down these now-hardened silos. An enterprise-wide effort to model the value chain at the top level is ongoing, but so far this has not filtered down through the business units and departments.

Process documents exist in some form within the departmental units; however, they are not published or shared, are in a variety of formats, and do not represent standard levels.

Our value proposition to the leadership included these benefits:

It’s a quick win. While a full standardized set of hierarchical process models are a good thing to have, there may not be enough process skill, tools, or resources to create them. Each of the diagrams presented here takes only a few hours to complete. A consultant interviews the SMEs and documents the results, the SMEs and process owners* review the result, and the document and its characteristics are published on a SharePoint site. These can take as little as 3 hours to draft, review, revise, and complete.

A process has a named, formal owner.Up until now processes have not had owners assigned. We named the manager of the department executing the business process as the process owner. Note that these are business managers. Naming them in an inventory allows owners of adjacent processes know who to talk to when a change is being considered, or when a question arises. Process maturity increases as managers begin to think of themselves as responsible for maintenance of a process and its deliverables, in addition to managing staff, budgets, and projects.

The process has context. The exercise of listing the suppliers and customers helps the process owner and SMEs think through where their process sits in the value chain. They also know who to involve when they consider a change to their process. Knowing who your customers are is the key to understanding and meeting their needs.

Feedback loops are visible. Asking what feedback process owners give to their suppliers on the quality of the inputs is revealing. In many cases, they are not getting what they need, but have no formal agreements on what, how, when, and how often they receive these inputs, and what their quality expectations are. Asking what feedback they solicit from their customers provides opportunity for a discussion on customer focus. An added benefit for process owners is that this feedback can demonstrate the value and quality of their process in a concrete, measurable way.

How Do I Begin Assembling a Process Catalog?

In our case, we took these steps to receive approval for a pilot project:

Do a little homework. We checked with other process and methodology groups across the enterprise to understand the scope of other efforts for modeling, improving, or cataloging processes. We discovered that a request was made from the C-suite to create an enterprise business process framework, and worked with that team to determine how our process catalog would fit into that framework. Since we are beginning our pilot with a single 7-unit department within IT, we agreed that our diagrams will fit into the 4th or 5th level once the enterprise model is further decomposed.

Write up the proposal. Our proposal included the problem/opportunity statement, benefits, costs, resources, a rough schedule, and a description of the deliverables. We submitted the proposal and received approval to begin the work at the beginning of the current fiscal year.

Gain commitment. We turned our proposal into a presentation and provided the highlights to the managers of the seven units within the pilot department. From each Manager, we gained commitment that they would provide:

- A list of the major cross-functional processes for which their unit is responsible

- A named owner within the business for each process

- A SME for each process

- A briefing to their departments, establishing the priority of this effort relative to other work

- Access to their SMEs to gather information about the processes.

Next Steps

In the next installment, we’ll dive into the details of the model and the elements of the inventory list. We’ll also provide our progress, tell you what’s going well, and where we’ve needed to adjust course. Stay tuned!

[1] Supplier, Input, Process, Output, Customer