In walking the line on Business Process Management (BPM) analysis and implementation, two valuable and non-technical skills are Experience and Judgment. Learning the latest techniques such as Agile, Lean and Six Sigma are filling the training pipelines. These skills are useful. Still, I recommend a second look at areas which are not currently in the forefront of practitioner popularity.

My topics are Systems Thinking and System Dynamics. These areas were first developed during the 1940’s and 50’s, by Jay Wright Forrester. He is currently not as famous as a founder of scientific management and quality such as Deming or Juran, Peter Drucker or Warren Bennis; nonetheless, his contributions to our systems knowledge and methodology are very important. He may be one of the least-known of key thinkers who moved science and technology forward during the latter half of the 20th century. (Please see the sidebar below for Forrester’s major accomplishments.)

Systems Thinking and System Dynamics

Systems Thinking has two key postulates:

- All systems regulate or adapt (or die), and

- The better adapted to one environment, the harder it is survive when the environment changes.

Other key attributes:

- The most important aspects of systems are relationships among the components, and

- Aspects of a single component must be coordinated with effects on the system as a whole.

- Systems may be parts of, or contain other systems, and finally

- Elements which do not relate within the system are separate, (but may be part of another system).

Forrester influenced many key aspects of military and academic thought. While the Dynamics part added excitement, it was the Thinking part which gave the results.

A Systems Thinking example, from nature, is the relationship between the Spotted Owl in Oregon, and its diminishing environment. Another is the influence on the Monarch Butterfly in Mexico’s dwindling habitat, and the plight of the African Elephant or Asian Tiger from poaching and disappearing habitat. Environment changes cause stress and ultimately, catastrophe.

A Systems Thinking example from business concerns “rare earths” — the impact on manufacture on items like cell phone screens, high powered magnets, and medical devices such as MRI’s, as components became fifty times more expensive. China, the single source of rare earths such as Disprobium or Yttrium, withheld supplies from buyers in the US and Japan, after a single incident over ownership of a barren island in the South China sea. The US is now trying to reopen a mine in California, closed earlier due to low prices from China. The closed mine will reopen in 2015, now that we know that a having only single supplier can be very costly and risky.

BPM, in my view, is a superset of the “feeding disciplines” which also are going strong in their own right. Among these are Business Analysis, (IIBA a key leader), Project Management (PMI in the forefront), IT as a driver, Business Architecture, and Quality (ASQ the prime US leader), some of which have gone on for more than a century, back when the technology instrument was the slide rule. Theories and formulas abounded. Judgment and staying power overcame many bubbles and fads. Strong, stable, and innovative organizations prevailed.

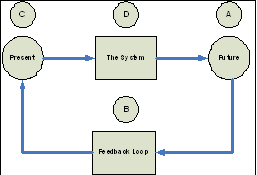

In our diagram here, the element most often overlooked is Step B, the Feedback Loop. So our progression through the key steps should really be:

- The Future — Where do we want to be?

- Feedback Loop — How will we know when we get there?

- The Present — Where are we now?

- The System — What are all the steps?

Figure 1: The Systems Development Environment

The key addition is Feedback. This defines the path, working backwards, from the goal to the present. Without this precise definition of what is to be accomplished, the objective remains vague and undefined. This is well known, as also in Steven Covey’s “7 Habits” book, as “Begin with the End in Mind.” Nonetheless, many of us don’t think this way under pressure. (Figure 1 may also relate to “PDCA” (Plan- Do-Check-Act) of Shewhart and Deming which invoke continuous feedback.)

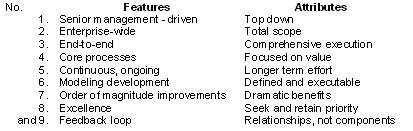

BPM’s advantages over the more time-boxed disciplines such as Project Management are highlighted in Table 1 below. This broader perspective affords Systems Thinking an environment to flourish in:

Table 1: BPM Strengths and Attributes

Looking at some specifics (the growth of expert analysis and practices of key BPM feeder groups –

– PMI, IIBA, BPMS modeling, major consulting firms, American Society for Quality, boutique BPMS companies, Business Schools like Stanford, MIT, Harvard Business School, Chicago U. – these entities have encapsulated some older practices , moving BPM as a mature, if not yet dominant, subject for business improvement.

BPM transcends the silo-oriented tools and practices, in order to cover the enterprise totality – end-to-end, longer range, core processes – with objectives to maximize the potential benefits of efforts and results.

Industry as a whole has not yet adopted Business Process Management principles whole-heartedly. Still, the component elements themselves are also vital to BPM objectives and goals. The silo-based disciplines, such as Marketing, Human Resources, Manufacturing, Accounting which emphasize the functional level of skills and results are also necessary and valuable to businesses. The drawback lies in the shortsightedness of looking only at each discipline separately, which leaves much synergy off the table.

However, treating the project as a self-contained unit exclusively will sub-optimize and confine to much smaller spans of improvement, due to the barriers of discipline specialization and time constraints. BA, PM, IT contribute to corporate benefit, but the silo mindset limits many possibilities. By understanding the constraints and boundaries of Systems Dynamics, the broader scope and possibilities expand to integrate connections and synergy.

Examples – Antiterrorist Protection and Others

A terrorist report of a “dirty bomb” threat to the port of Baltimore in mid-2000’s, fortunately a false alarm, raised many interesting questions with profound systems implications. Very little evidence remains, because the incident was quickly covered up. Most of us never heard about it.

Here’s what happened over nearly three days: The port was closed to shipping for a short time. But if one of the millions of shipping containers that enter the US each year were to bring in a terrorist weapon, it would raise quite a stir.

It turns out, though, that the most serious problem might not be the loss of life, as terrible as that would be, but the economic follow-on from the event, not the event itself. As the Coast Guard kept ships from entering, products spoiled, schedules were disrupted, just-in-time deadlines were missed, and business hundreds of miles away were forced to shut down for lack of materials. Roads were clogged, rail deliveries were cancelled, truck drivers were idled, and so forth.

The most fundamental question, it turned out, was “Whose job was it to make decisions?” Was the decision to reopen the port to be made by the Coast Guard, the Harbormaster, the Mayor of Baltimore, the Governor of Maryland, or the Director of Homeland Security? How would the elements be coordinated, and who would communicate them? Finally the port was re-opened and the backlogs were eliminated. Each unit had its commitments, but the overall system was not evaluated end-to-end.

If a similar but real event happened in Los Angeles, New York, or New Orleans, what steps must take place to mitigate the damage? What activities, both physical and financial, should take place to recover? How much GDP should be diverted to prevention and to realistic civic planning for first responders, equipment, civil mobilization, and survivors? These questions are still not understood or dealt with systematically.

Some progress is being made across State, Local and Federal boundaries, but many impediments remain. One path to improvement would be to do “what if” planning and testing on many levels. (This would also increase employment opportunities.)

An example of failure is the fire and explosion in West, Texas. Dozens of homes are (were) within a half-mile of a Fertilizer storage plant, which exploded in April, 2013. Dozens of homes burned to the ground. This is the same experience which took place in Toulouse, France, which blew up in 2005, killing 31 and injuring over 2000 from flying glass. How many other locations have accident-prone storage facilities, and what can be done to mitigate the risk? Apparently, we didn’t learn anything from the French incident.

People live on the shore line now under increased risk of continuous flooding. What long range plan will be put in place? What flood control will be put in lower Manhattan, which was submerged under two feet of water during Hurricane Sandy, causing over a billion dollars in Subway flooding? Finally, whose job will it be to find out and determine how to make necessary changes?

System Dynamics can review a whole area of problems in a consistent way. It is the intersection of Content, Process, and Structure, with the goal in mind, to determine who does what, and what is needed.

Sidebar: Jay Wright Forrester (1918 – ) His accomplishments: Forrester got his start developing theory and practice under the pressure of WW II. As a civilian professor at MIT, he considered “feedback loops” He developed servomechanisms used in developing radar, flight simulators and early computers, including magnetic core storage, which accelerated early computer technology. By the late 1940’s, military interest in computer development began to wane. Then, USSR’s detonation of the Atomic Bomb in 1949 instantly changed all that, and the arms race was off and running, dragging computerization along with it.

Forrester was one of the founders of the MIT Sloan School of Management, was an influential in activities of MITRE Corporation (Originally MIT Research and Engineering). He collaborated with John Von Neumann on the ENIAC computer development; and finally, with Kenneth Olsen, who later became the founder of Digital Equipment Corporation. (It’s OK if you don’t know of these guys, but they did make much of our current technology possible).

In 1989 he was awarded the National Medal of Technology, among many other honors.