A SIPOC diagram represents a high-level view of a process. It shows the Suppliers, Inputs, Process, Outputs and Customers. The SIPOC Diagram plays an important role in Process Definition/Improvement and should ideally be done first before embarking on extensive process mapping. An analyst – in collaboration with other stakeholders – may use it to arrive at a consensus on the process before moving to a greater level of detail. To emphasize putting the needs of the customer foremost, the tool is sometimes called COPIS and the process information is filled in starting with the customer and working upstream to the supplier. It is very helpful to give people who are unfamiliar with a process a high-level overview.

Under what scenarios might you use a SIPOC diagram?

- Scenario 1: When creating a new process from scratch.

- Scenario 2: When defining the scope of a project. When the goal of project is process improvement, mapping it would provide an indication of the scope.

- Scenario 3: When documenting/assessing an existing process prior to the improvement effort.

o On drawing a SIPOC diagram, you’ll be able to tell at a glance, who your project will affect (stakeholders), which outputs add value and which – if any – do not add value, which steps are redundant and where supplier performance is unsatisfactory.

General Rules for Drawing a SIPOC Diagram

- Keep it as high-level and simple as possible; it should contain between 5-8 steps, ideally.

- Avoid drawing it on your own. You could organize a brainstorming session to generate ideas on the elements of the diagram before you start.

- Customers receive or use the outputs of the process; your customers are not just buyers of your product or service, but are also recipients or users of the outputs produced at every step in the process. They are regarded as stakeholders.

- Inputs are the key requirements needed for the process to work and represent what suppliers provide.

- Suppliers are those who provide inputs; they are also stakeholders.

- Outputs are the results of process steps and can be used as basis of discussion with customers to identify their requirements; every output must have a customer.

- The Process name should be in the “From-To” form. The cell for each process step is split into 2 sub-cells. The top sub-cell is the name of the role or performer that does the work. The bottom sub-cell is the name of the work. The name of the work should be in the form “verb-noun”. For example, the name of Order Fulfillment should be “Order-to-Deliver” and a step in that process would be “Enter Order”. The name of the role doing the work would be Order Entry Clerk. A hiring process might be “Hire-to-Orient”, a step might be “Interview Candidates”, and the role might be Hiring Manager etc.

- Staff and other resources are not inputs, as they are not “worked on” by the process; Business rules should also not be regarded as inputs – they guide the process but don’t get “worked on” by it.

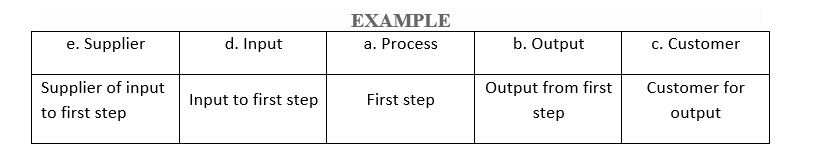

Approach for building a SIPOC diagram

- Organize a brainstorming session comprising participants who are knowledgeable about the process

- At the center of a whiteboard, draw a diagrammatic view of the process with input from everyone; all participants should agree on how the process works.

- Using that diagram write the steps in sequence down the center column of the diagram (a)

- Identify the outputs (b) – what are the outcome(s) of each step?

- From the outputs, determine who the customers are (c)

- For each step in the process, determine what inputs (d) are worked on – think of materials, data and anything else you need to execute the process.

- Suppliers (e) – those that provide inputs to the process. It may be the team of people that perform the steps in the process, IT department, etc. In some situations, Customers may be described as suppliers to a process.