In a previous article, Using Business Architecture to Design Future Industries, I made the case that Business Architects have an important role to play in identifying future-oriented business opportunities in emerging business sectors such as the $350B space industry. The example provided was that of a key business process – the space supply chain management process – which is already being defined and modeled by several organizations. While the space industry and its key sector – space transportation – are still in their infancy, industry players with the foresight to map out the long-term business and IT architecture for the space transportation infrastructure will have first-entrant advantage into what is expected to be a highly lucrative field.

In this article I will take a step back and talk about how Business Architects can assist their companies or clients in spotting and leveraging such opportunities in new or adjacent markets. The tools-of-the-trade I am going to discuss here I am going to borrow from disciplines such as market analysis, enterprise architecture, and future-thinking.

Trend-watching

Unlike bird-watching which can be pursued on weekends, trend-watching requires continuous attention and perseverance. By scanning business and technology (at a minimum) news and articles on a daily basis, our brains get trained in detecting fluctuations in the discourse surrounding a particular area of human activity.

As an example, my own interest in the outer space dates back many years, but it stayed dormant until I started noticing a spike in the frequency of news on reusable rocket technologies. This compelled me to research the topic deeper and uncover several related trends:

- Advances in spacecraft design: Faster, cheaper, reusable is the current mantra for space agencies and rocket-makers alike, and the drive for increased efficiency and cost reductions has led to strikingly innovative spacecraft designs. Virgin Galactic has developed a rocket-powered space plane – the VSS Unity – which takes off attached to its mothership, WhiteKnightTwo; once it reaches an altitude of 43,000 feet, the plane is released from the mothership and its pilots switch on VSS Unity’s rocket engine to drive the vehicle directly upward at supersonic speeds. Other companies, such as SpaceX and BlueOrigin, have elected instead to develop reusable launch vehicles that use Vertical Takeoff, Vertical Landing (VTVL) technology to land themselves at target locations. SpaceX’s Falcon 9 rockets have successfully used retrorockets to land on their launch pads multiple times, aided by advanced machine learning algorithms to determine the best way to land the rocket, with real-time computer vision data assisting in route prediction. These technical achievements have been made possible by innovative engineering upgrades to the vehicle, including grid fins, cold-gas thrusters, and landing legs[i].

- Better propulsion technologies: As recently as 2010, NASA considered liquid hydrogen to be the fuel of choice for the American space program. Hydrogen presents the benefit of having the lowest molecular weight of any known substance and burns with extreme intensity (5,500°F). In combination with an oxidizer such as liquid oxygen (LOX), liquid hydrogen yields a very high specific impulse – or efficiency in relation to the amount of propellant consumed. NASA’s Space Shuttle’s main engines, the European Ariane 5, and the Chinese CZ-5 launch vehicles used hydrogen+LOX (hydralox) as fuel, as well as Blue Origin’s BE-3PM engines. However, over the last decade, rocket-makers such as SpaceX (for its Raptor engine) and Blue Origin (for the BE-4 engines) have been experimenting with using methane+LOX (methalox) as propellants. Methane requires much smaller tanks than hydrogen, and the methalox combination is more stable in space than hydralox which means it doesn’t require highly insulated cryogenic tanks the way hydrolox does, thus making the overall design lighter. Should SpaceX’s spacecraft ever reach Mars, SpaceX plans to manufacture oxygen and methane fuel using water from Martian soil, carbon dioxide in the planet’s thin air, and electricity from solar panels.

- Advances in manufacturing technology: Not only have propulsion systems seen significant advances, but new developments in materials science, such as additive manufacturing, have assisted in the manufacturing of stronger, lighter, and less expensive vehicle parts. Rocket Lab, maker of suborbital sounding rocket Ātea and of lightweight orbital rocket Electron, already 3D-prints all major components of its Electron rocket’s Rutherford engine. Additive Rocket Corporation, another manufacturer of rocket engines and engine components ,combines additive manufacturing with generative design, where computer algorithms test designs to find the optimal solution.

By observing these three trends and considering their forward trajectories, it becomes apparent that that they reinforce each other and together they contribute to making space transportation more affordable.

Enterprise Architecture – the Zachman Framework™

Now, just having the insight that the world is moving towards more affordable space transportation is not in itself a ‘eureka’ moment. Such an insight has to be brought down to human-size level to assess whether it is truly actionable.

Enter the Zachman Framework™, whose purpose, in the words of its creator John Zachman, is to transform an abstract idea into an instantiation, i.e., into something tangible. One of the fundamental concepts in the Zachman Framework™ is that the identification and representation of complex ideas requires answers to the primitive interrogatives[ii]: what, how, when, who, where, and why.

In my example, to take my insight regarding the advent of affordable space transportation further, I needed answers to at least two questions: WHAT does “affordable” mean, and WHEN will the cost space transportation hit the affordability threshold.

The first question was relatively easy to answer. A further scan of the publicly available interviews with space industry luminaries[iii]pointed to the figure of $100 per pound of materials/people sent into outer space to an altitude of at least 1,200 miles – what is called the Lower Earth Orbit (LEO) – as the target.

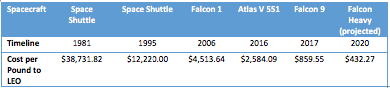

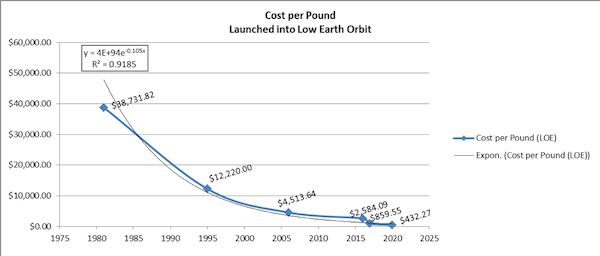

The second question – when would the industry reach the cost point of $100 per pound to Lower Earth Orbit – required a bit more digging. Eventually I found several sources[iv],[v] listing the timeline of space launches and estimated costs of transportation per kilogram and/or pound. The following table shows key data points in the history of space launches:

By plotting these values onto a graph, the picture that emerged was that of an exponential decline in costs starting with the 1980s. Thanks to Microsoft Excel, I was easily able to visualize the trend line and obtain the formula for it, y = 4E+94e-0.105x.

The only step left was to try out different timelines (x = 2025, x = 2026, x = 2027, etc.) to approximate the value of the x-axis (i.e., the year) for which the corresponding value on the y-axis would drop below $100 per pound of stuff sent into outer space. As it turned out, according to the trend line, the threshold of $100 per pound would be crossed by year 2031– a reachable and reasonable time-horizon for planning in an emerging industry, and by year 2035 the cost per pound would fall below $70. The high value (91.85%) of the R2 coefficient associated with the regression analysis performed by Excel to determine the trend line indicates that the regression model fits the actual data quite well, so even though the cost projection for future years is an approximation – it is a reasonably good approximation.

It is worth noting that this cost projection assumes that current spacecraft manufacturing methods remain more or less unchanged for the next sixteen years. The reality may in fact be quite different. Henry Ford revolutionized the automobile manufacturing industry by shifting from artisanal means of production, where cars where crafted one at a time, in-situ, to an assembly-line model where workers performed specialized tasks using standardized components thus producing cars in one fifth of the time it used to take before. In a similar vein, one can easily envision a near-future scenario where 3D printing and industrial-scale automation can significantly speed up the production of spacecraft, and drive down costs at a much faster rate than the graph above may suggest.

Futures Wheel

Once the business insight has been identified through trend-watching, and further confirmed and better defined by asking the primitive questions, it is time to put our foresight caps on and look into the future.

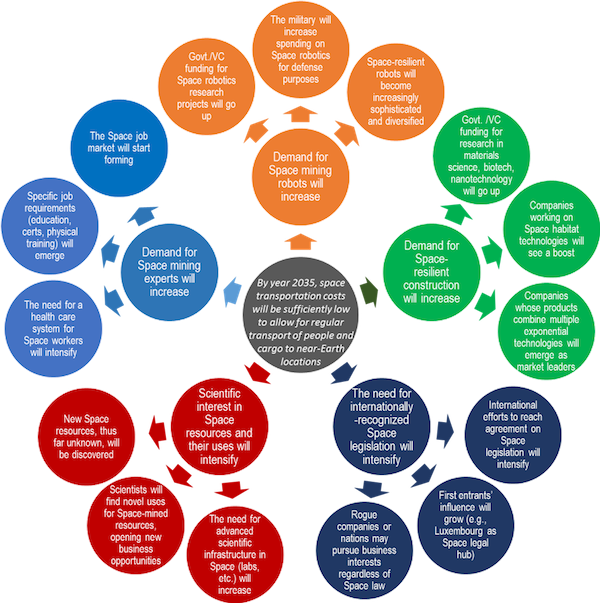

One tool for foresight that has been in use since the early ‘70s is the Futures Wheel, invented by Jerome C. Glenn – founder and Executive Director of The Millennium Project. The Futures Wheel is a method to develop a graphical visualization of the future by considering the consequences of an event or trend.

To create a Futures Wheel diagram, one has to start with a premise– for instance “by year 2035, space transportation costs will be sufficiently low to allow for regular transport of people and cargo to near-Earth locations”. The premise is captured at the center of the “wheel”, and serves as the basis for deriving first-order consequences. This first level of consequences can be deduced by asking practical, intuitive questions. In the example above, such questions might include:

- What types of businesses or organizations would benefit from the affordability of space transportation?

- How would they benefit from it?

- If we can send people into outer space, what types of activities would they engage in to provide a positive return-on-investment?

- What type of education or training would these people need to have, to be able to perform their tasks?

- How would they be provided with shelter and supplies during their outer space stay?

- Could any of the envisioned work be done just as reliably and economically by robots?

- What rights and duties would these organizations (and their workforce) have with regards to their work and presence in outer space?

Answering each one of these questions may require further, more in-depth research and potentially additional trend analysis, as although the question are qualitative in nature, the real value comes from drawing on knowledge and expertise to draw answers.

For a Business Architect looking to uncover business opportunities for his or her clients, the first few questions listed above are critical, as they seek to identify the primary business domain served by the premise. In the example provided in this article, my research points to space resource mining (in short, “space mining”) as a potentially very lucrative business that both governments as well as private enterprises can benefit from, so my Futures Wheel diagram will focus on space mining[vi].

Asking the basic, practical questions as shown above with space mining as the primary business domain, it becomes apparent that the logical first-order consequences of the premise “by year 2035, space transportation costs will be sufficiently low to allow for regular transport of people and cargo to near-Earth locations” are that:

- There will be an increased demand for space mining experts and personnel

- In parallel, the demand for robotic devices capable of performing those space mining activities that can be automated will go up as well

- Given that space mining operations in any given location will be of some duration, there will be a need for long-term accommodations for both people and wares

- A more robust set of laws and treaties will need to be established, to govern national and international space mining operations and mitigate political, social, environmental and other risks arising from space resource exploitation and utilization

- The scientific knowledge and financial benefits derived from space mining will have a feedback effect on the scientific community, spurring the creation of new technologies and more expansive space exploration plans

As the Futures Wheel below shows, the first-order consequences following directly from the premise are positioned around the premise and linked to it, while the consequences of those first level direct consequences are positioned at the next outward level and linked to the first level consequence. The exercise can be repeated with third-order and fourth-order consequences, until the level of detail in the diagram is concrete enough to draw actionable conclusions.

The first-order and lower-order consequences can be more densely interconnected to reflect inherent interrelationships, however for the purpose of this illustration I left out the interconnections to keep the diagram uncluttered.

Once the Futures Wheel is fully defined, it can be utilized to drive strategic business decisions and to underlie the development of specific organization plans or processes that would position the business so as to leverage the foreseen consequences in a lucrative manner.

For example, a training company or a higher learning institute interested in positioning to support the space industry would want to invest in developing courses and certification programs geared to the specifics of space resource mining. A company specialized in robotics might want to expand their line of products to include mining robots that can be withstand extreme environmental conditions and function in low-gravity environments. (Or, even better, robots that can be 3D-printed and assembled in space, on location). A company that is already vested in creating tools, products or services for space resource mining would want to connect with the ‘Space law’ legal community, and consider establishing an office in one of the countries providing financial backing and favorable regulatory structures to the space industry, such as Luxembourg, Belgium or the U.S.

***

The three analysis methods presented here are simple to use and intuitive, and they provide a Business Architect who wants to do more than document the present and near-future with a way to provide strategic, long-term value to clients and employers, by layering practices from adjacent disciplines over the traditional, tried-and-true Business Architecture methods.

[i]Post, H. (2015, June 11). Reusability: The Key to Making Human Life Multi-Planetary. Retrieved January 28, 2019, from https://www.spacex.com/news/2013/03/31/reusability-key-making-human-life-multi-planetary

[ii]This article condenses the analysis to only two questions – what and when – for illustration purposes. For a complete analysis, all the primitives should be assessed and addressed.

[iii]Kestenbaum, NPR, D. (2011, July 21). Spaceflight Is Getting Cheaper. But It’s Still Not Cheap Enough. Retrieved March 3, 2019, from https://www.npr.org/sections/money/2011/07/21/138166072/spaceflight-is-getting-cheaper-but-its-still-not-cheap-enough

[iv]Jones, H. W. (2018, July 12). The Recent Large Reduction in Space Launch Cost. 48th International Conference on Environmental Systems. 8-12 July 2018, Albuquerque, New Mexico.

[v]Fox, W. (2018, September 1). Launch costs to low Earth orbit, 1980-2100. Retrieved March 1, 2019, from https://www.futuretimeline.net/data-trends/6.htm

[vi]Keszthelyi, L., Hagerty, J., Bowers, A., Ellefsen, K., Ridley, I., King, T., Trilling, D., Moskovitz, N., and Grundy, W., 2017, Feasibility study for the quantitative assessment of mineral resources in asteroids: U.S. Geological Survey Open-File Report 2017–1041, 28 p., https://doi.org/10.3133/ofr20171041