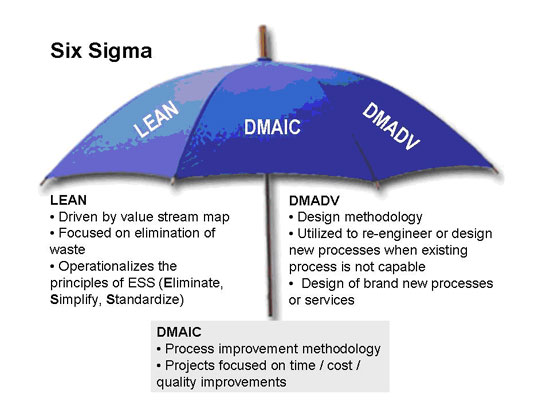

Both the Lean and the Six Sigma methodologies have proven that it is possible to achieve dramatic improvements in cost, quality, and time by focusing on process improvement. Six Sigma is focused on reducing variation and improving process yield by following a problem-solving approach using statistical tools, Lean is primarily concerned with eliminating waste and improving flow by following the Lean principles and a defined approach to implement each of these principles.

The financial savings companies such as Toyota, General Electric, Motorola, and many others have accomplished using these methodologies have inspired many other firms to follow suit. As a result, many companies have either a Lean or Six Sigma program in place. But, using either one of them alone has limitations:

- Process Improvement: Focused on problem solving, aimed at eliminating the vital few root causes. It is most common to use the DMAIC roadmap:

o Define – Select customer’s critical-to-quality characteristics (CTQs). Define the process improvement goals that are consistent with customer demands and enterprise strategy.

o Measure – Create a measurement system and validate the system. Measure the current process and collect relevant data for future comparison.

o Analyze – Identify the sources of variation from the performance objectives. Analyze to verify relationship and causality of factors. Determine what the relationship is and attempt to ensure that all factors have been considered using one or more of the tools in the Six Sigma toolkit.

o Improve – Discover process relationships and establish new and improved procedures. Improve or optimize the process based upon the analysis.

o Control – Sustain the gain by implementing process controls. Control to ensure that any variances are corrected before they result in defects. Set up pilot runs to establish process capability, transition to production and thereafter continuously measure the process and institute control mechanisms. - Process Design/Redesign: The creation of a new process to achieve exponential improvement and/or meet the changing demands of customers, technology and competition. It must handle totally dysfunctional processes and reengineer them. It is also known as Design for Six Sigma (DFSS). DMADV is the most common roadmap followed for DFSS:o Define – Define the goals of the design activity that are consistent with customer demands and enterprise strategy.

o Measure – Measure and identify CTQs, product capabilities, production process capability and risk assessments.

o Analyze – Analyze to develop and design alternatives, create high-level design and evaluate design capability to select the best design.

o Design – Design details, optimize the design, and plan for design verification. This phase may require simulations.

o Verify – Verify the design, set up pilot runs, implement production process and handover to process owners. - Six Sigma will eliminate defects but it will not address the question of how to optimize process flow.

- Lean principles exclude the advanced statistical tools often required to achieve the process capabilities needed to be truly ‘lean’. Lean approaches work in the following categories and tries to reduce the non value added work.

o Value Added = process steps that definitely create value for customer and the enterprise.

o Non Value Added = process steps that create no value and can be eliminated (waste).

o Business Value Added = process steps that create no value but are necessary.

– Required for legal requirements, financial reporting, etc.

– Required by the current state of the system, inspections, transportation, etc.

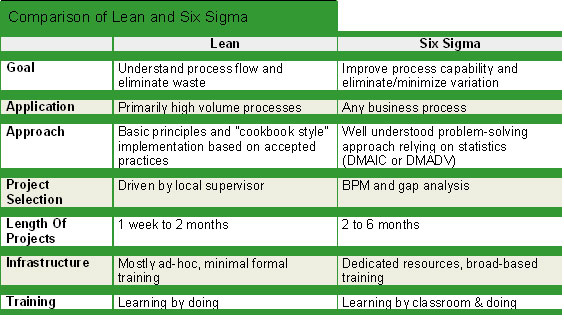

Most practitioners consider these two methods, Six Sigma and Lean, as complementing each other. Each approach can result in dramatic improvement, utilizing both methods simultaneously holds the promise of being able to address all types of process problems with the most appropriate toolkit. As a result, many firms should be looking for an approach that allows them to combines both methodologies into an integrated system or improvement roadmap. Comparison between Six Sigma and Lean indicate some differences:

One of the most powerful ways to improve business performance is combining business process management (BPM) strategies with Six Sigma and Lean strategies. BPM strategies emphasize process improvements and automation to drive performance, while Six Sigma uses statistical analysis to drive quality improvements. Lean’s emphasis is on the removal of waste to drive process improvement. These strategies are not mutually exclusive, however, and some savvy companies have discovered that combining BPM with Six Sigma and Lean can create dramatic results.

Developing an integrated improvement program that incorporates both Lean and Six Sigma tools, in addition to BPM requires an integrated improvement strategy has to take into consideration the differences and use them effectively:

- An integrated improvement program needs to be fueled by a vision of the future state and by a pipeline of specific projects that will help close the gap between current and future state. BPM introduced Process Mapping as the central tool to identify the gaps and to develop a list of projects that can be tackled using Lean or Six Sigma methodology.

- Lean projects are very tangible, visible, and can be completed within a few days (typically Six Sigma projects require a few months).

- An integrated approach should emphasize Lean projects during the initial phase of the deployment to increase momentum through some quick wins.

- Lean emphasizes broad principles coupled with practical recommendations to achieve improvements. For example, Lean suggests looking at work as “Value Added, Non Value Added, and Business Value Added.”

- Lean principles are often inadequate to solve some of the more complex problems that require statistical analysis. Six Sigma needs to be incorporated to ensure that the improvement roadmap includes an accepted problem-solving approach.

- The Six Sigma process and tools can be applied to virtually every process and industry, the Lean approach is much more specific and the content needs to be adjusted to industry needs.

- Training is effective but only when combined with application.

o Lean principles are typically taught as separate workshops, with each workshop combining a short training session on the principle with direct application on the shop floor.

o Six Sigma training is broken down into the phases of the DMAIC process with time between each training session to apply the tools learned to the project. The extensive analysis required for Six Sigma projects suggests that a workshop structure as used for Lean training would not be effective.

o Six Sigma training then continues with advanced tools used in DMADV, also known as Design for Six Sigma (DFSS).

The integrated approach to process improvement (using Lean and Six Sigma) will include:

- Using Business Process Management (BPM) to develop a pipeline of projects that lend themselves either to applying Six Sigma or Lean tools.

- Rolling out Lean principles first to increase momentum, introducing the Six Sigma process later on to tackle the more advanced problems.

- Adjusting the content of the training to the needs of the specific organization – service or manufacturing.

Business Process Management includes a set of tools to document, measure, monitor, and control processes. It establishes ongoing accountability for managing entire cross-functional processes to satisfy customer and process goals, and explicitly ties the results of the Key Process Indicators (Y’s) to the strategy of the organization. We need to use BPM to identify the areas where our enterprise needs further improvement – the project pipeline.

Six Sigma provides a set of tools to make and sustain dramatic improvements to business processes. Lean provides an established methodology for removing waste from processes. When Business Process Management, Six Sigma and Lean are used together they provide the basis for improved performance and growth.

Both Lean and Six Sigma represent significant commitments on the part of a business or organization, and they take time to implement them thoroughly. Tremendous organizational change is often required, leading most companies to start with a single department or pilot project and expand their use over a multi-year period. It is well worth the time and effort, though, to generate the substantial business improvements that are typical with Lean and Six Sigma.