Operational Excellence is not easy to define. Some descriptions are too broad. Others are so narrow that the ultimate definition seems too focused in scope. Often, we end up with definitions that seem plausible in an academic sense, such as “Being world class,” “Being the best globally,” or, “Excellence in everything we do,” but these are difficult to translate into specific practices.

To properly define Operational Excellence, there is value in looking at the evolution of the term.

In “The Discipline of Market Leaders – Choose your Customers, Narrow your Focus, Dominate your Market“, Michael Treacy and Fred Wiersema described three distinct value propositions or disciplines an organization could choose to compete in their market or industry – Operational Excellence, Product Leadership, and Customer Intimacy.

They maintained that market leaders needed to excel in delivering extraordinary levels of performance in one of these three value propositions, while maintaining competitive standards in the other disciplines.

Based on Treacy’s and Wiersema’s findings, market leaders will try not to pursue a diffused business strategy across two or even all three disciplines, but will continually focus on their organizational design, processes, technology and competencies to improve the one particular value discipline where they wish to excel.

Organizations pursuing an Operational Excellence differentiation strategy are able to deliver a combination of price, quality, and ease of purchase and service that no other organization in their market or industry can match.

Additional insight into the elements of the operational excellence management philosophy can be found in:

- The Shingo Prize for Operational Excellence

- Malcolm Baldrige Nation Quality Award

- The EFQM Excellence Model

Achieving Operational Excellence requires the successful implementation of a Business Execution System that effectively and seamlessly integrates the following four building blocks:

- Strategy Deployment

- Performance Management

- Process Excellence

- High Performance Work Teams

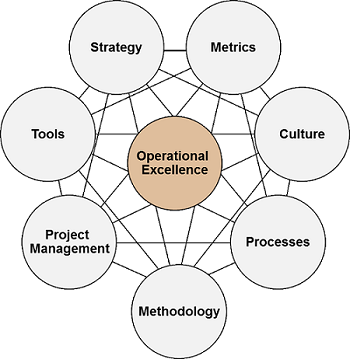

Operational Excellence is an element of organizational leadership that stresses the application of a variety of principles, systems, and tools toward the sustainable improvement of key performance metrics.

This can be boiled down to seven areas that organizations must excel at:

- Strategy – leadership creates vision and values and refine it into strategic focus and direction

- Metrics – balanced scorecards cascaded down through the organization

- Culture – staff understand the strategy and accountable for the results

- Processes – integrated business process architecture (BPM)

- Methodology – applying discipline and rigor to continuous improvement through Lean Six Sigma (LSS)

- Project Management – applying discipline and rigor to projects (PMBOK)

- Tools – solution delivery (processes, products and services), problem solving and continuous process improvement

It is also essential to understand that these areas are all interconnected. In order for an organization to claim it operates in the Operational Excellence space it must excel at all seven of these areas.

The model below shows the interconnection of all of these areas of expertise.

These seven areas of focus when combined effectively create the model for Operational Excellence. If we expand on the seven elements we see the application of many management tools and techniques:

- Strategy – we can apply tools, such as, the McKinsey 7 S, Balanced Scorecards, and Strategy Maps.

- Metrics – the use of Balanced Scorecards and Key Process Indicators (KPI’s) from BPM.

- Culture – includes leadership, change management, consensus building, motivation, and team building.

- Processes – defined, measured, continuously improved and controlled processes using the disciplines of Business Process Management.

- Methodology – There are several methodologies, the most commonly used are: BPM, Kaizen, Lean, Value Stream Mapping, Six Sigma, Lean Six Sigma and Process Improvement Tools. Many organizations have found that using combinations of these together gives the optimum result.

- Project Management – A rigorous and disciplined approach to project management is required in order to apply the methodologies and tools required to be successful. The most widely recognized is the PMBOK (Project Management Body of Knowledge from the Project Management Institute).

- Tools – Organizations that are good at continuous improvement have an established set of tools that they use to work on process improvement projects. These are also the tools used by BPM and Lean Six Sigma methodologies.

Process Improvement tools:

- Working with Ideas – Brainstorming, Affinity diagram, Multi-voting

- Process Flow Tools – SIPOC diagram, Process map, Process flow analysis, Value added analysis

- Voice of the Customer (VOC)

- Data Collection – Operational definitions, Check sheets, Sampling, Measurement systems analysis, Pareto Charts

- Descriptive Statistics and Data Displays – Histogram, Run Charts

The focus of Operational Excellence is to help the organization by:

- Maintaining focus on return on investment (ROI) and productivity while reducing costs

- Get greater re-use from technology investments to increase operational effectiveness

- Align operating model to support growth

In summary, Operational Excellence will help an organization to:

- Deliver measurable improvements — OPEX links operations to strategy, and establishes performance metrics to help organizations stay on track to meet or exceed their goals.

- Add capability and flexibility to our operating model — OPEX can help improve quality, costs and time to deliver, as well as, identify potential savings while still promoting growth and innovation.

- Building effective organizations — OPEX focuses on organizational and service delivery model changes that drive results, with emphasis on the cross functional nature of the processes used to produce products and services for our customers.