BPM and Lean Six Sigma are not the same, but should they be enemies or partners?

BPM is defined by BPMInstitute.org as:

Business Process Management is the definition, improvement and management of a firm’s end-to-end enterprise business processes in order to achieve three outcomes crucial to a performance-based, customer-driven firm:

- clarity on strategic direction,

- alignment of the firm’s resources, and

- increased discipline in daily operations

Lean methodology focuses on increasing flow through the process, reducing cycle time and eliminating wastes in the process. Six Sigma focuses on identifying and removing the causes of defects and minimizing variation in the process. So the three methods each have a different focus, but their overall purpose is the same –improve work processes using data, customer insight, workflow understanding, and removal of wastes (defects, or issues).

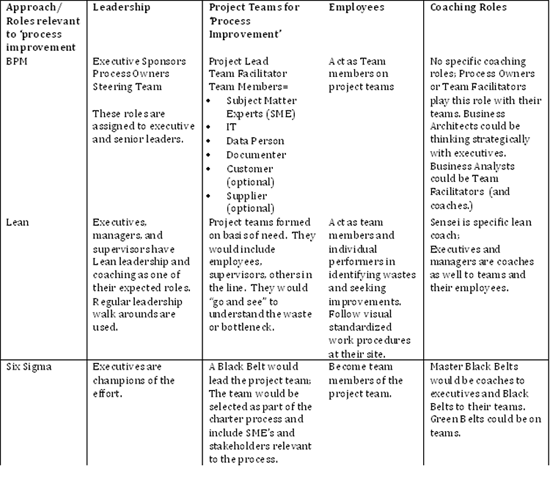

The table below gives a quick indication of key areas of similarities and differences in the three approaches.

BPM, Lean and Six Sigma have three different programmatic names and like different religions they represent three different perspectives: Lean comes from the Toyota Product System, Six Sigma comes from the Motorola and General Electric programs, BPM has the technology leadership of Gartner and others.

There is similarity and complementarity between the three approaches in the Leadership, Project Teams, and employee elements as well, represented in the table below.

Experienced Lean or Six Sigma practitioners could take a Team Facilitator role for a BPM Project Team. The concept would not be to run the team or operationalize the improvements or ensure that the Process Owner’s goals are met—that is the Project Lead’s role. Rather they would bring the methodology to the process improvement effort. And the process improvement effort would not be exclusively Lean or Six Sigma. Rather they would bring those techniques to the BPM effort where appropriate.

Additionally since BPM has both operational and technology improvements it would be useful for the Lean Six Sigma person to learn some additional skills (if they don’t already have them) as listed below:

- How to model processes using particular software

- When to use the full BPM methodology vs. a shortened version

- How to keep the project on track with the Project Lead

- Selecting which techniques to use; keeping to what is relevant vs. just using more techniques

- The craft of BPM- not only using the techniques, but knowing how to customize them, seeing the red flags

- Interactions with and presentations to senior management

- How to assist in change management

- Where integration with other applications is needed in the process

- How data integrity and management is important in the process

- Using a shared repository

BPM, Lean and Six Sigma have a lot in common. The practitioners who know one methodology have techniques to share in working in another methodology. They can benefit from experience in each approach, and then follow one methodology if their organization is wedded to that, or join the best of several approaches to the benefit of their organization and the customer.