The popularity of Six Sigma continues to increase within large corporations as a means of improving quality and reducing costs. As most readers will know by now, Six Sigma has been adopted by leading corporations such as GE, Sun Microsystems, Allied Signal, Bank of America, Motorola, etc.

In the current business environment, IT organizations have been less passionate in adopting Six Sigma methods. Many organizations feel that they can’t afford the luxury of a Six Sigma Program. There is a feeling that it intended for the product or service areas of the business.

Yet, IT organizations should consider that the business process principles that underlie the Six Sigma approach and some of the specific tools within the Six Sigma tool-kit represent a powerful way for their business partners to significantly improve performance.

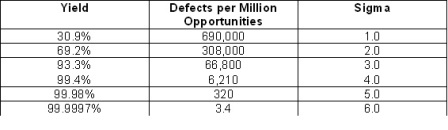

First – a quick refresher on ‘what is Six Sigma’. The Greek letter SIGMA is a mathematical term that simply represents a measure of variation, the distribution or spread around the mean or average of any process or procedure. The term Six Sigma defines an optimum measurement of quality: 3.4 defects per million events. If one could reduce the standard deviation (average deviation in the product) then less of the product will be faulty. In other words, do it right the first time by progressively monitoring and eliminating mistakes.

The methodology is based on the combination of well-established statistical process control techniques, data analysis methods, and the systematic training of all personnel at every level in the organization involved in the activity or process targeted by Six Sigma. It is a well-structured, data-driven methodology for eliminating defects, waste, or quality problems of all kinds in manufacturing, service delivery, management, and other business activities.

Ideally, Six Sigma is based on customer knowledge and accurate measures of core processes performance in providing what customers need and demand. Understanding what is “Critical to Quality” (CTQ’s) for the customer is one of the cornerstones of successful Six Sigma initiatives. The degree of linkage between Six Sigma and Business Process thinking often determines the span and depth of performance improvements. Both incremental business process improvement and Six Sigma are intended to develop focused solutions to eliminate root causes of business performance problems, while keeping the existing business process and organization structure in place.

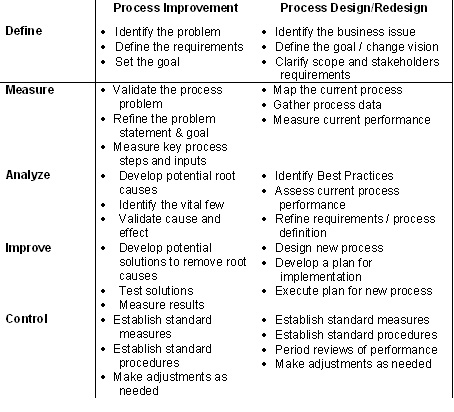

The key steps of the Six Sigma approach are Define, Measure, Analyze, Improve and Control [DMAIC]. In other words, the intent is to basically identify an area where there is a problem, measure it, identify the root cause of the problem, then fix it and control it. These steps are outlined in further detail on the chart below.

Six Sigma – DMAIC Key Steps

IT organizations should consider the benefit of Six Sigma because processes with high error rates can represent significant opportunities for performance improvement. Automating a poorly performing process without reducing the error rates is a bad idea. The introduction of business process thinking into the business environment should be easier for IT to do in concert with BPM. Start by identifying the core business processes, the ones that deliver value to the customers. These tend to be cross-functional in nature. Understanding that to produce value for the customer work must pass through various departments is crucial to any improvement effort. Then, identify the scope of improvement needed for the core business processes to deliver on strategic commitments.

Since many enterprises operate their business processes at the 3 to 4 sigma level, an improvement of even one sigma represents a huge step forward in improving customer satisfaction and reducing costs. Through a better understanding of their core processes, smaller businesses can make significant improvements rapidly. For example, if a businesses which has an order fulfillment process (a core process) operating at 3.0 sigma or 66,000 defects per million opportunities [DPMO] could improve performance to the 4.0 sigma level [6,210 DPMO], it would realize a gain of approximately 10X performance. Imagine if each error cost as little as $10.00 to fix, then the cost savings would be in the range of $600,000.00.

So, how should an IT organization get started?

First, identify the key business processes, for the enterprise. The core processes are those that deliver value directly to the customer. Do not confuse them with the support processes, those that are required to run the operation, such as Human Resources, Budgeting, Facilities, etc. Most companies have around 5 to 8 core customer / mission critical business processes such as order fulfillment, new product development, etc. Then map these processes at a mid level and measure the current process results.

Then, you must decide on the required scope of improvement and whether to perform process improvement or process redesign (see the table below for the differences). Process improvement usually fixes a segment of a larger process, while process redesign encompasses building a new process to replace the old one. Initially, businesses are well advised to begin by performing process improvement using basic six sigma methodology (DMAIC), measure the results and quantify the savings.

While these steps appear straightforward on the surface, they are far from effortless. In fact, the following are just some of the elements needed for success.

- Visible Management Commitment

- A keen sense of urgency

- Clear definition of customer requirements

- Shared understanding of core processes and key customers

- Honesty in measuring current performance

- Discipline in prioritizing the critical few improvement projects

- Communicating the success stories / proving that it works

- Rewarding and recognizing the performers

- Institutionalizing the approach

These factors can sometimes be challenging for businesses where the leadership team is susceptible to ever changing priorities. Yet, the potential rewards are significant.

Businesses shouldn’t be deterred by the some of the myths surrounding Six Sigma. One of these is that ‘you need Black Belts and Green Belts’. While this is true for some corporations, where the Six Sigma approach actually prescribes the development path for Black Belts and others, consultants may be used to get the program off the ground. Six Sigma tools are not totally new; they build on well known Total Quality Management (TQM) techniques from the 1980’s and Statistical Process Control tools from the 1930’s and 1940’s

Nor is it necessarily true that you must train everyone and it takes weeks to train employees properly. Businesses can take advantage of ‘just in time’ practices for the application of Six Sigma – if properly structured and delivered.

A third common misconception or ‘myth’ is that setting big goals may prevent the success of Six Sigma. Smaller businesses are well equipped to place their Six Sigma efforts clearly within a business process framework, allowing it to contribute to the achievement of very aggressive goals.

While it is true that solving problems takes time, it is not true that the application of Six Sigma takes more time than most businesses personnel can afford. After all, if you don’t have time to figure out how to do it right the first time, when will you find time to do it over and over again?

The largest intangible win which may result from the application of these practices for many small to medium sized businesses may indeed be related to senior management’s increased comfort and application of business process thinking. Leaders will be prompted to ask and answer the following questions.

- Which core business processes are instrumental in achieving strategic targets?

- What degree of improvement is needed with respect to these critical business processes?

- To what extent does the current organization design support or impede the performance of these critical business processes?

- To what extent do current corporate policies support or impede the performance of these critical business processes?

- To what extent do current reward systems support or impede the performance of these critical business processes?

The current business environment demands an even greater dedication to product and service quality. The combination of Six Sigma and business process thinking offers smaller businesses an opportunity to drive out complacency when it comes to quality. Successfully implemented, businesses can expect to both raise the bar in terms of service excellence and concurrently realize significant cost savings.