You’ve been asked to improve how your organization works. But where to start? Do you just lock yourself away in a closet and attempt to figure out what’s going wrong or do you create an interactive web survey to elicit large volumes of improvement ideas? Based on our experience, we’ve found the most effective path to improvement lies somewhere in between. Using collaborative group working sessions, you can make better decisions and ultimately increase acceptance of change, by effectively leveraging the knowledge of your internal experts.

So where do you start? Whether you are an executive wanting cross-organizational change, a manager responsible for improving your area of responsibility or a project manager tasked with making the change happen, collaborative process improvement will require these three steps.

Identify a Guidance Team. This team will serve as your advisors, advocates and communication vehicle throughout the improvement effort. The group should be small; between 6-8 members. For large, cross-organizational improvement efforts, each member of the Guidance Team should:

- have a stake in or own the processes being changed,

- have the authority to make process-related decisions, and

- have the ability to approve the resulting change implementations.

For improvement initiatives of a smaller scope, limited to your area of responsibility and authority, the composition and role of the Guidance Team may change. Rather than decision-makers and owners, the team will be comprised of a select group of experts who know the processes. They will still serve as advisors, advocates and change communicators; however, you will be the ultimate decision-maker.

At the beginning of the effort, this team will help you define the scope, improvement goals and necessary resources for your effort. During the change definition, this team must be actively involved in understanding and assessing the impacts on the desired targets. During implementation, this team is crucial to presenting a consistent internal message about the change –why it was needed, what its goals are, how it will impact the organization.

Identify the Improvement Team. Collaboration among folks who view the process from differing aspects is critical to true improvement. In fact, in the book The Wisdom of Teams, James Surowiecki’s research found that “if you can assemble a diverse group of people who possess varying degrees of knowledge and insight, you’re better off entrusting it with major decisions than leaving them in the hands of one or two people, no matter how smart they are.”1

The Improvement Team will work with you to analyze the issues and identify improvement opportunities. They represent a diverse set of experts on how processes really work and may include…

- Business Experts that perform or interact with the process regularly.

- Support Partners (such as Finance or Technology) who can identify the impacts of change.

- Suppliers or Vendors to whom you outsource segments of the process or on whom you receive input or provide output.

- A Project Manager and/or Quality Professional (Black Belt) who’ll ensure the improvements get implemented & measured.

The optimum team size is between 8 and 12. If you have more than 12, progress may slow down. If you have less than 8, you may not have all the representation needed.

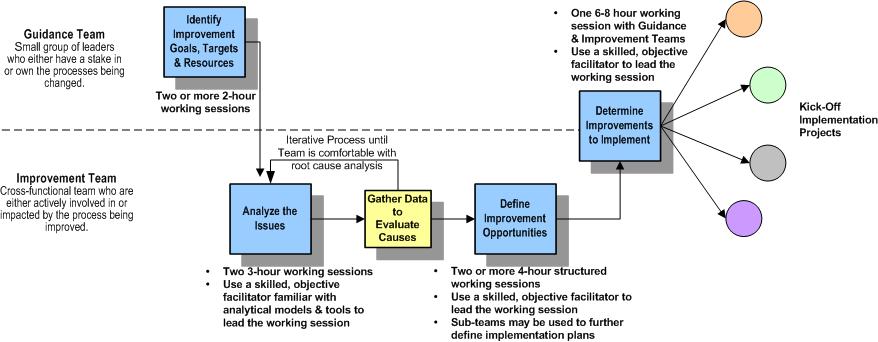

Hold Collaborative Working Sessions. These working sessions may range from 2 hours to 1 day, depending on the objective. Figure 1 illustrates a typical approach to collaborative process improvement.

Figure 1 – Collaborative Approach to Process Improvement

1. Identify Improvement Goals and Targets. Work with the Guidance Team to define the high-level “what” and “why” for this improvement effort. The team will need to describe:

- What are the perceived process issues (i.e., Not meeting promised ordering, manufacturing, delivery or service targets consistently enough? High volume of returns? Too many resources required? Frequently unpaid invoices? )

- Why do the issues need to be addressed now?

Once you’ve identified the issues, review the process metrics to understand how the process is currently performing in these areas and set your improvement targets accordingly. For example, let’s say that research has revealed a large number of customer complaints surrounding timeliness and accuracy of orders. Current metrics confirm that on-time order delivery occurs 78% of the time and that 10% of your orders are returned as incorrect. Based on this, you may set the following goal and targets for your effort:

- Goal: We will improve product delivery by ensuring that the right order gets to the customer within the estimated timeframe.

- Targets: 98% on time delivery and 1% shipping errors.

2. Analyze the Issues. Hold collaborative working sessions with the Improvement Team to identify the possible “roots” of the various issues. This may involve mapping out segments of the process to better understand the sequence, systems and roles involved and/or various forms of root cause or statistical process analysis.

Take a break from meetings to gather hard data. This will allow the team to better understand which suspected causes are truly contributing to the problem. Then reconvene a working session to review the results and identify the most likely causes.

3. Define Improvement Opportunities. Bring the Improvement Team together once again to brainstorm ways to minimize or eliminate the roots of the problem. Assess these potential solutions against the improvement goals and targets to determine which ones will provide the most gain. For these priority solutions, work with the team or break into sub-teams to create a high-level implementation plan with associated metrics, anticipated benefits, supporting assumptions and proposed timeline. If appropriate create a process map to reflect how the process will work if the various improvements are implemented.

4. Determine Improvements to be Implemented. Bring both the Guidance and Improvement Teams together to walk through the results of the analysis. This meeting should be in an informal discussion, question and answer format. The goal is a shared understanding of the various improvement opportunities and, if possible, a decision to either implement or table the various improvement solutions. In some cases further research may be needed to answer questions before a final decision can be reached.

At this point you’ll be ready to kick off the improvement projects using your standard project management methodology.

1 Surowiecki, James, The Wisdom of Teams. Doubleday: June, 2004.