Documenting a process generally results in at least a 25% gain in productivity – and often even greater gains. Translating work effort into discrete steps reduces confusion, drives consistency of execution, accelerates training, and usually uncovers efficiency opportunities along the way. But it comes with a risk – the risk of improving a segment of an organization to the detriment of other areas. We call this a localized improvement.

To eliminate the occurrence of localized improvements, our teams ALWAYS begin the process transformation journey by creating an Enterprise Process Map (also called an Enterprise Process Blueprint). An enterprise process map is a birds-eye pictorial view of how an organization delivers value for a customer. In contrast to an organizational chart, it is not the view to identify the hierarchical reporting structure (at least in most instances) but rather it is the embodiment of the market and operational approach currently in existence for an organization. Good enterprise process maps depict the workflows from the acquisition of raw material to the delivery of a product or service and on through the ongoing servicing of the customer’s needs.

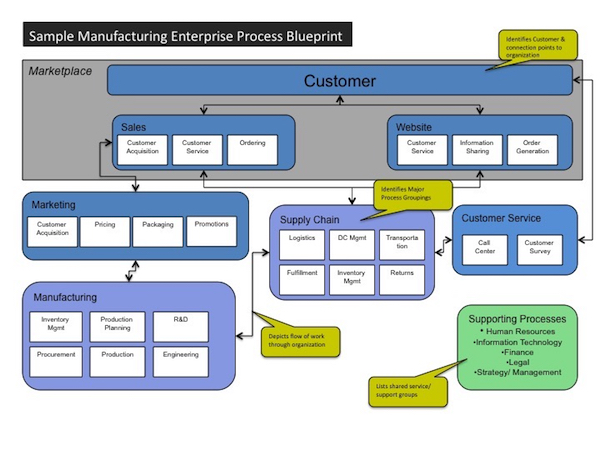

An example of an Enterprise Process Map for a manufacturing company is depicted below.

An enterprise process map…

- Starts with the customer and identifies moments when the organization and the customer interact on a regular basis (this is very useful for creating a cohesive and consistent customer experience).

- Provides an end-to-end view of the processes spanning an enterprise (and even business partners).

- Identifies how work flows through these processes to the end delivery of a solution for a customer.

By documenting an enterprise process map, an organization reaps several immediate benefits.

- Clarity – Having a widespread perspective of how the organization operates in a business as usual environment is critical to having intelligent and informed debate about the future path of the organization.

- Customer Connections – Delivering a consistent and intentional brand requires an awareness of all the times the customer and the organization interact.

- Capabilities Blueprint – Providing an operational view of the organization drives awareness of the capabilities of the organization. This view is foundational to understanding the opportunities and challenges of adjusting the strategic course of the organization.

- Mitigates risk of localized improvements – By understanding how the pieces of the operational puzzle fit together, improvement teams can identify the processes potentially impacted by a change and ensure there are not unintended consequences to their improvement activities

- Ownership Identification – While the enterprise process map is not necessarily a replacement for the organizational chart (although it can be), it can be used to map process managers to end-to-end processes, major processes, or sub-processes. In doing so, leaders anointed with authority are aligned to the value engine of the organization making it possible to more rapidly address adjustments to product and service offerings.

Once an enterprise process map is created, confirmed, and made available to the employee population, it routinely becomes the background for ideation activity. From experience, our team has found permutations of the enterprise process map to add additional insight. For example, we often adjust the size of a process box to align with the headcount, budget or identified opportunities for that process. By overlaying these views of the enterprise process map, potential gaps in resource allocation become immediately visible.

Due to the clarity and benefits delivered by the creation of an enterprise process map for an organization, it has become the first step on any process-based exercise I undertake. In my next article, I will share our step-by-step approach to create an enterprise process map as efficiently as possible.